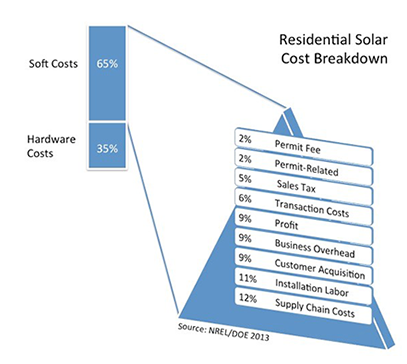

The hardware cost of solar has dropped over 70 percent in the last several years. Now, the spotlight for cost reduction opportunity has moved into the area of “soft costs,” which a 2013 national study underwritten by the National Renewable Energy Laboratory showed comprise over 64 percent of the cost of a residential photovoltaic, PV, system. Soft costs are defined as all the non-hardware costs of delivering a solar project, including customer acquisition, supply chain, installation labor and permitting related costs, to name a few.

While analysts have been long on talk analyzing what they are and how they are impacting the industry, they have been short on solutions. Why? Because residential solar is very complex, requiring business owners to understand and interact with an ever-changing landscape of regulatory and policy issues. On top of that, operating within the solar industry requires increasing understanding of the finance, construction and high-tech aspects that come together.

Since there is no common formula to apply to reduce soft costs nor a single soft cost category that should be universally tackled first by all companies, installers should use a more individualized approach to evaluate their project delivery process for cost reduction areas. This is the first article in a three-part series introducing you to how you can analyze your business using tools and techniques from Lean.

Step 1: Defining the customer

Before looking for improvements or searching for wasteful activities, you should define the various customers that exist both internal and external to your organization. These relationships are key to meeting customer expectations. For example, design staff drafting plan sets must meet the needs of the authority having jurisdiction, utility, installers and the final customer. Without seeing the authority having jurisdiction, utility and installers as customers of their product, the designer could overlook important safety or design requirements in order to meet a customer-specified design constraint, which may cause rework and delays if in conflict with authority having jurisdiction or utility requirements or real-world installation practices.

When each employee frames the recipient of their work as a customer—whether the final customer who bought the photovoltaic system or an internal customer like another colleague—they are more likely to see how their activities could be value-added or non-value added. When framed in this way, a business owner and management team can collaborate more effectively to streamline handoffs and minimize or remove re-work related to misalignment of goals.

Step 2: Defining value

All processes can be categorized as value-added or non-value added. What does the customer value? It’s very simple:

- On time

- On budget

- Done right

- No defects

What you value or believe is valuable may be different from what your customer values. It’s critical when you go through this exercise to remove yourself from your own business operation bias as much as possible.

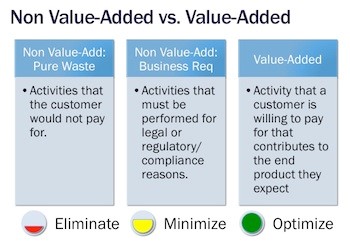

A value-added process is an activity that a customer is willing to pay for that contributes to the end product they expect. For example, a designer putting together a permit package for a local authority having jurisdiction is a value-added activity. It transforms the customer’s order or desire into a product that moves the project closer to the execution of the installation event, the ultimate value-added process. Seek to optimize value-added activities.

Non-value-added processes, on the other hand, fall into two categories: business requirements and pure waste.

Business requirements are often found in the overhead of the company. Examples include managing your fleet of vehicles, human resources efforts (like fees on payroll and benefits systems, recruiting fees or administration of employment paperwork) and/or compliance-related activities if you deal with project finance. You still need to perform these activities because your business cannot run without them. You should always seek to minimize these activities as much as possible.

Examples of pure waste are excessive coordination meetings, generating reports that are not read or acted upon, multiple layers of approval and any kind of re-work. You should always seek to eliminate these activities.

A technique used to understand how to see non value-added activities is the Seven Forms of Waste, which we will explore in greater detail in our next segment.