When building a new home, proper alignment of the primary air barrier and thermal barrier is critical to maximizing performance and comfort. By following best practices, you can reduce the amount of air changes per hour (ACH) for a tighter, more efficient home that meets EPSTM requirements. To earn an EPS, a home energy performance score, you’ll need to achieve less than 4 ACH. The first step is to identify the location of the primary air barrier. In most cases, the exterior sheathing is the best place to target.

When building a new home, proper alignment of the primary air barrier and thermal barrier is critical to maximizing performance and comfort. By following best practices, you can reduce the amount of air changes per hour (ACH) for a tighter, more efficient home that meets EPSTM requirements. To earn an EPS, a home energy performance score, you’ll need to achieve less than 4 ACH. The first step is to identify the location of the primary air barrier. In most cases, the exterior sheathing is the best place to target.

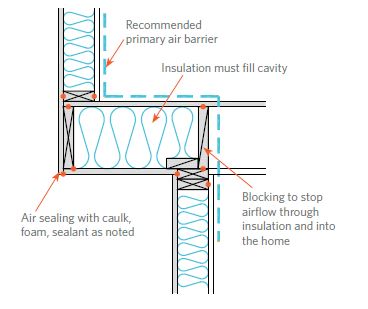

Given the number of subcontractors who work on a house, it’s important to coordinate properly so that the primary air barrier is defined and that everyone understands their role in creating and maintaining it. Crews often need to cut holes in framing to route their equipment, which creates penetrations where air can move unimpeded, increasing air leakage rates. Even skilled sealing crews can have difficulty sealing every area that’s been cut. Installing the primary air barrier at the exterior sheathing will circumvent the potential issues that arise from relying on multiple trades allies, or the air sealing crew, to meticulously air seal as they move through the home.

Exterior sheathing is also a more logical and effective place to accomplish air leakage reduction because the sheathing is a continuous visible plane. The best results are often achieved by taping the seams of the sheathing, foaming any other penetrations that have been created in the shell and between conditioned/unconditioned space, and adding sill sealer to the top plate to adjoin the sheetrock. Finally, the home is air sealed within the envelope as an extra measure to reduce any other leakage such as convective movement between floors.

For more information on air barriers and how to achieve other energy-saving EPS requirements, visit the EPS Field Guide or call Energy Trust’s trade ally coordinator at 1.877.283.0698.